TRSB - Shuttle Block Pump Manufacturer

Working Principle

“DEV ” make The TRSB Series Shuttle Block pump employs an unique pumping principle - a combination of Rotary and Piston pump. Two double acting pistons in their respective slots at right angles to each other, accomplish this, while the rotor turns without the need for any valving. The Shuttle block pump is a self priming rotary pump. There are only three pumping elements - Rotor, Piston and Shuttle. Rotor is keyed to a single shaft and runs concentric in pump casing. It has a rectangular slot across its face. The channel-shaped piston reciprocates within this slot. A rectangular block, shuttle, fits liquid tight in piston slot and reciprocates. The rotary action of rotor combined with the eccentrically mounted shuttle creates reciprocating motion among the pumping elements.

The mechanical principle of the SHUTTLE BLOCK Pump incorporates the pump casing, the rotor, the piston, and the shuttle. The rotor is a liquid-tight fit within the casing, with the piston and shuttle being equally liquid-tight in their fit to each other and to the rotor. In operation the piston slides back and forth in the rotor slot and discharging from the opposite end. At the same time the shuttle slides back and forth within the piston slot. Choose Dev Pumps for a trusted Industrial applications of Rotary Shuttle Block Pumps TRSB in Ahmedabad, Delhi, Mumbai, Kolkata, Chennai, Bangalore, Indore, Ludhiana, Pune, and Coimbatore.

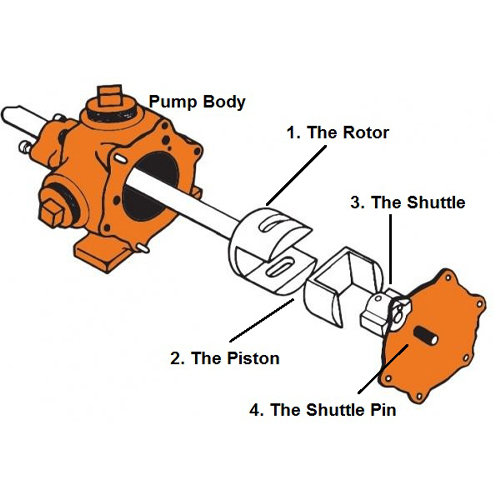

Part View

1. The Rotor

The Rotor Integral with the Pump’s shaft is slotted across its face. Two vents lead out from the slot sides to the rotor periphery, The rotor has liquid tight fit within the Body Bore and performs as rotary valve, channelling the pumpage from the intake port around and our the discharge port

2. The Piston

The Piston is U – Shaped, reciprocate in the rotor slot. As it slides back, the receding piston face draws liquid into the slot while passing the intake port and traps a charge of liquid in the slot end. Revolving the output side of the pump. The piston moves forward and pushes the liquid out the discharge port. The opposite face of the double-acting piston performs similarly at the opposite rotor slot end.

3. The Shuttle

The Shuttle is Rectangular block nested inside the U of the piston, It Slides transversely within the piston, drawing liquid through one rotor vent while discharging through the opposite vent.

4. The Shuttle Pin

The Shuttle Pin is fixed in the pump head / end Cover paralle to but not coaxial with th rotor shaft. The shuttle is bored to accommodate this pin and rotate on it. When the rotor revolves , the eccentric position of the pin causes the shuttle to reciprocate within the piston and the piston to the reciprocate in the rotor slot, providing four overlapping positive displacement strokes per revolution

Advantages

- Smooth Discharge Characteristics with minimum pulsation hence will not chew , aerate for foam the material pumped.

- Extremely High volumetric efficiency saving Power.

- Virtually no mechanical beating makes for successful pumping of liquid which are shear sensitive or degraded by centrifugal , gear or paddle agitation common in the other pumps.

- Highly viscous liquids are easily handled as well as thin volatile materials.

- Self-Priming and High Suction Lift capacity.

- Large Area of Contact between matting parts means exceptionally long service life because of law unit pressure between pumping members exactly opposite to the high unit pressures encountered in the gear pumps.

- Large mating areas trap fluid in to hydro-dynamic support, preventing metal to metal contact prolonging pump life.

- Only three Pumping members ensures maintenance free operation, with practically no down time.

- Well supported on extra-long bronze bush bearings and ball bearing hence practically noise less operation .

Benefits

- Handle highly viscous liquids.

- Low noise and vibrations.

- Smooth, pulsation-free flow.

- Front pull out design, rotor removal without dismantling the pump and motor.

- High reliability and excellent service life.

- High volumetric efficiency, low power requirements.

- Long stuffing box construction with external bearing reduces leakges to minimum.

Applications

The TRSB Series Rotary Shuttle Block Pumps are used in Loading , Unloading , Transfer, Circulation and process pumping of wide range of products Asphalt-Hot, Bitumen, Caustic Soda, Chocolate, Corn Syrup, Coal Tar Pitch, Crude Oil, Enamel, Edible Oils, Fatty Acid, Fuel Oil (LDO, LSHS, HHS, RF, O), Glue-hot, Grease, Kerosene, Lacquer, Lard-hot, Linseed Oil, Lubricating Oil, Molasses, Naphtha, Palm Oil, Paint, Petroleum, Printing Ink, Resin, Shellac, Soap Liquor, Sodium Silicate, Starch, Sugar Syrup, Tar, Turpentine, Varnish, Wax, etc.

Materials of Construction

- Casing : Cast Iron , Cast Bronze

- Shaft : Ally Steel / SS-410 / SS-304 / SS-304

- Rotor : Cast Iron , Cast Bronze

- Shuttle : Cast Iron , Cast Bronze

- Pin : Gland Packing or M. Seal

- Shaft seal : Cast Iron , Cast Bronze

- Bearing Housing : Cast Iron

Technical Data

| Pump Model | Pump Size In mm Suc X Disch Flange End. | Pump Speed Max. In RPM | Capacity In L.P.M. @ Max. Speed | Pressure Max In Kg/cm2 | Ele. Motor HP Recommended @ Op. Pressure where tested in Lube Oil having Viscosity 40-50 CST | |||

|---|---|---|---|---|---|---|---|---|

| 2.0Kg/Cm2 | 4.0Kg/cm2. | 6.0 Kg/cm2 | 8.0 Kg/cm2 | |||||

| TRSB-01 | 50 x 50 | 960 rpm | 250 LPM | 8.0 Kg/cm2 | 2.5HP | 3.5HP | 5.0HP | 7.5HP |

| TRSB-02 | 80 x 80 | 740 rpm | 450 LPM | 8.0 Kg/cm2 | 3.0HP | 5.0HP | 5.0HP | 10.0HP |

| TRSB-03 | 100 x 100 | 576 rpm | 1000 LPM | 6.0 Kg/cm2 | 12.5HP | 20.0HP | 25.0HP | N/R |