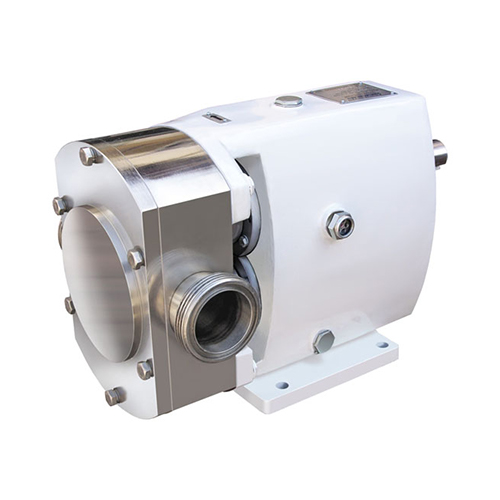

SS Rotary Lobe Pump Manufacturer & Supplier

Dev Engineers is one of the leading SS Rotary Lobe Pump Manufacturer & Supplier of Stainless Steel Rotary Lobe Pump in Ahmedabad, Delhi, Mumbai, Kolkata, Chennai, Bangalore, Indore, Ludhiana, Pune, and Coimbatore.

We provide excellent quality with efficient production capacity of SS lobe Pump. Our manufactured SS Rotary Lobe Pump can deliver the accurate functioning output for its applications.SS Lobe pumps are popular in these diverse industries because they offer superb sanitary qualities, high efficiency, reliability and corrosion resistance.

Types of SS Rotary Lobe Pumps

- Bi Stainless Steel Lobe Pump

- Tri Stainless Steel Lobe Pump

SS Lobe Pump Working Principle

SS Lobe Pump consists of two synchronized rotors present in Lobe pump, this lobe rotate in opposite directions inside a casing. The rotors have lobes that interlock and create a series of cavities, when the cavities move the liquid moves from the inlet side to the outlet of the lobe pump. The cavities have a decreasing volume, it creates a vacuum that sucks the liquid into the pump. All Parts of the product are made form AISI-316 quality stainless steel alloys to meet exacting requirements of hygienic standard.“ DEV ” DELB Series Stainless Steel Rotary Lobe Pumps are positive displacement pump technology used widely across the pharmaceutical, food and beverage industries. The pumps action means they are capable of handling shear sensitive materials with low shear.

The rotors are provided with so-called lobes, which rotate past each other without touching each other. The shape of the lobes can vary and the number of lobes can also differ. Due to this design, the lobes of the two rotors intertwine, thereby pumping the liquid in axial direction.Choose an Dev Stainless Steel Rotary lobe pump for reliable performance and gentle pumping action of low, medium and high-viscosity fluid media. SS Lobe pumps has Robust construction, modular design and flexible configuration enhance process flexibility and operational reliability. Rotary lobe pump are virtually pulsation-free handling of all types of process fluids, no matter of the viscosity. These are Designed for easy maintenance and long lifespan service, these pumps have a best performance envelope to meet a broad range of process requirements.

SS Rotary Lobe Pump Features

- More the number of lobes, higher the chances of less pulsating discharge.

- Max. Capacity up to 100 m3/hr.

- Handle Viscosity up to 200000 cps.

- Standard Max. Temperature to 110 Deg C.

- Jacketing Feature available if liquid has Crystallisation nature.

- All Wetted Parts AISI 316.

- Hard Face Hygienic Mechanical Seals.

- SS lobe pumps are placed vertically.

SS Rotary Lobe Pump Technical Specification

| Pump Model No. | Port Size Standard Suc x Disch. | Capacity in LPM @ 100 rpm | Max. Speed RPM | Max. Pressure In Kg/cm2 |

|---|---|---|---|---|

| DLB-100 | 1” x 1” | 08 | 1000 | 7.0 |

| DLB-150 | 1 ½” x ½” | 18 | 1000 | 7.0 |

| DLB-200 | 2” x 2” | 38 | 1000 | 7.0 |

| DLB-250 | 2 ½” x 2 ½” | 79 | 1000 | 7.0 |

| DLB-300 | 3” x 3” | 168 | 650 | 7.0 |

| DLB-400 | 4” x 4” | 354 | 550 | 7.0 |

Applications of SS Rotary Lobe Pump

DLB Series SS Rotary Lobe Pump are Frequently used in food, dairy & pharma application because the handle solids without damaging the products and without shearing

- Food processing.

- Beverages.

- Dairy Produce.

- Personal Hygiene Products.

- Pharmaceutical.

- Chemical.

- Industrial.